Semiconductor Packaging Manufacturing Field

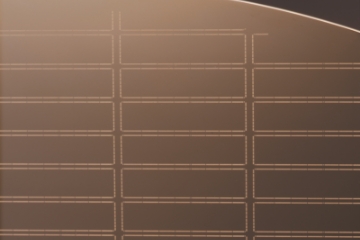

The process of separating the wafer into individual semiconductor chips, and place them into protective package. Photoresists and other chemicals provided by TOK are also used in this area.

Semiconductor manufacturing flow

Packaging Process

- Photoresist coating

- Exposure

- Development

- Plating process

- Photoresist cleaning

- Coating on the back

- Dicing

- Molding

- Photoresist coating

- Exposure

- Development

- Plating process

- Photoresist cleaning

- Coating on the back

- Dicing

- Molding

Process.15Photoresist coating

Apply a photoresist to the silicon substrate after the completion of the upstream process.

Process.16Exposure

Circuit design of photomask is transferred to coated photoresist film by irradiation of light.

Process.17Development

The photoresist pattern is formed by development.

Process.18Plating process

Using the resist pattern as a mold, form connector on pillars known as BUMPs.

Process.19Photoresist cleaning

Use a cleaning solution to remove any photoresist that is no longer needed.

Process.20Coating on the back

Coat the backside of the silicon substrate with the sealant.

Process.21Dicing

Wafer is diced into chipsize components.

Process.22Molding

Set and fix cut-out semiconductor chips onto a substrate

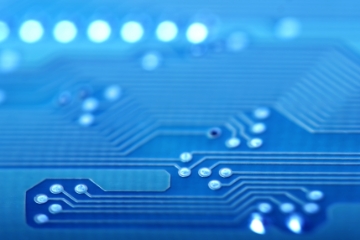

Packaging technology to render semiconductor

chips smaller, thinner, and capable of delivering higher performance

Flip-chip mounting

(Wireless bonding)

The finished semiconductor chip needs to be powered on by having it make contact with the substrate.

This used to be typically done by connecting the chip

to the frame using thin metal wires according to a method known as wire bonding.

These days, however, flip-chip mounting,

which entails the use of protruding connection terminals (bumps) instead of wires,

is predominantly used in this field.

Connecting semiconductor chips to substrates: the changing face of technology

We are helping to make semiconductor packages smaller and capable of delivering higher performance.

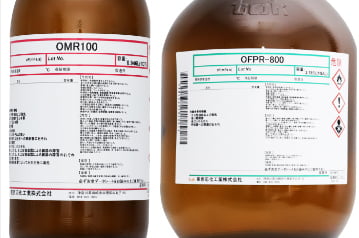

TOK’s Products in Semiconductor Packaging Manufacturing Field

Core Technology

The world leading micro-fabrication and high purification technologies

Our products, which are used to semiconductor manufacturing featuring cutting-edge circuits produced at a scale of several nanometers, are supported by two global-leading core technologies.